冲击挤压

几十年来,我们一直是这种冷成型工艺的技术先驱,并且一直在为其寻找激动人心的全新应用场景。

冲击挤压的优势

高效的制造工艺

在冲击挤压中,几乎只使用机械式肘杆压力机。它们比传统的液压机更快、更准确。使用机械式肘杆压力机的冲击挤压是中批量和大批量生产零件最有效的制造工艺之一。对于小型部件,我们的肘杆压力机可实现高达 330 冲程/分钟的节拍时间,并提供恒定的机器可用性。诺文铝业拥有全球最大的机械肘杆压力机,最大压制力为 2,000 吨。

强度和延展性

铝材冲击挤压是一种铝材冷锻工艺。铝材在室温下发生塑性变形,此时会发生冷作硬化效应,这是因为铝的晶格结构中发生了错位移动。在此期间伴随着强度增高,同时延展性降低。如果对材料要求更高,我们可以使用定制的热处理工艺。

密封性/无气孔

使用冲击挤压工艺制作的部件中不会有气孔或污染。因此,我们的部件无疑可以用作安全部件和压力介质存储部件(气密外壳)。在这方面,部件的后续加工也会造成影响。我们的冲击挤压件在机械加工后总是光滑且没有孔隙和凹坑,而采用铸造工艺则可能会在切削加工时造成缺陷,留下穿孔表面。

形状公差

由于铝材在冲击挤压过程中是在室温下成型的,所以成型后不会发生收缩。成品件的形状公差与模具的形状公差完全一致。这意味着通常不需要其他加工过程。

薄壁板

根据部件尺寸,可以压制非常薄的壁板(小于 0.5 mm)并保持相同的机械性能。从而为外壳内部留下了更多空间,再加上高导热性,这正是冲击挤压工艺的一大优势。

工具成本低

许多客户对我们相对较低的工具成本感到惊讶。我们一直致力于开发越加坚固耐用的工具,这些工具在我们的内部工具车间使用最先进的机床制造。

冲击挤压的优势

高效的制造工艺

在冲击挤压中,几乎只使用机械式肘杆压力机。它们比传统的液压机更快、更准确。使用机械式肘杆压力机的冲击挤压是中批量和大批量生产零件最有效的制造工艺之一。对于小型部件,我们的肘杆压力机可实现高达 330 冲程/分钟的节拍时间,并提供恒定的机器可用性。诺文铝业拥有全球最大的机械肘杆压力机,最大压制力为 2,000 吨。

强度和延展性

铝材冲击挤压是一种铝材冷锻工艺。铝材在室温下发生塑性变形,此时会发生冷作硬化效应,这是因为铝的晶格结构中发生了错位移动。在此期间伴随着强度增高,同时延展性降低。如果对材料要求更高,我们可以使用定制的热处理工艺。

密封性/无气孔

使用冲击挤压工艺制作的部件中不会有气孔或污染。因此,我们的部件无疑可以用作安全部件和压力介质存储部件(气密外壳)。在这方面,部件的后续加工也会造成影响。我们的冲击挤压件在机械加工后总是光滑且没有孔隙和凹坑,而采用铸造工艺则可能会在切削加工时造成缺陷,留下穿孔表面。

形状公差

由于铝材在冲击挤压过程中是在室温下成型的,所以成型后不会发生收缩。成品件的形状公差与模具的形状公差完全一致。这意味着通常不需要其他加工过程。

薄壁板

根据部件尺寸,可以压制非常薄的壁板(小于 0.5 mm)并保持相同的机械性能。从而为外壳内部留下了更多空间,再加上高导热性,这正是冲击挤压工艺的一大优势。

工具成本低

许多客户对我们相对较低的工具成本感到惊讶。我们一直致力于开发越加坚固耐用的工具,这些工具在我们的内部工具车间使用最先进的机床制造。

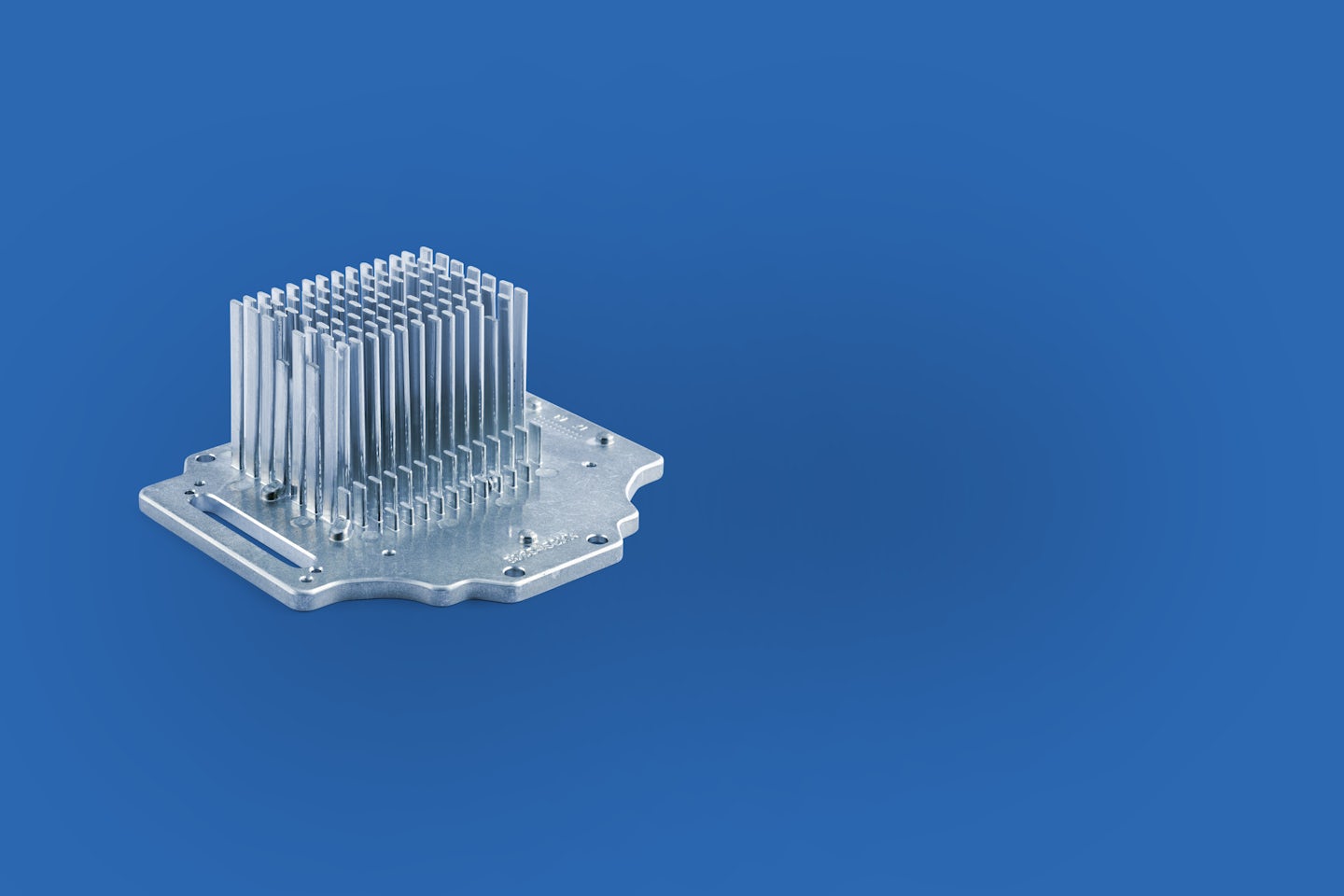

电力电子散热器

电力电子散热器

散热器采用挤压技术以纯铝制成,其导热率比铸造散热器高出 30 %,这意味着部件可以设计得更小、更轻。冷却销可以压制为不同的长度,采用圆形或星形规格。在背面,可以形成用于安装电路板的几何形状。此工艺主要应用于 LED 前照灯、电力电子设备、现代乘用车和卡车的控制系统。

最佳解决方案

替代深冲

对于较长的部件和不同于壁板的底面几何形状,工具成本较低。

替代铝材压铸

壁板薄、无铸角、公差小、冷却后无收缩、工具成本低、无气孔和空腔、结构均匀。

替代 CNC 铣削/车削

节省材料,生产数量较多时,在经济上有优势。

替代热锻

重量更轻,涂层工艺的表面性能更佳,公差限制更精确,节能。

创新

创新

使用现代模拟软件和我们在材料科学和工具制造领域的高水平专业知识,可以在中批量和大批量生产中制造复杂的几何形状。

行业解决方案

电动汽车

电池盒、电机外壳、铝制和铜制散热器

ADAS

传感器外壳、雷达和摄像机外壳、激光雷达组件

底盘部件

空气弹簧组件、铰接式前叉、转向和制动元件、减震器

安全

安全气囊外壳、微型气体发生器、皮带张紧器、制动元件

电气技术

散热器(铝和铜),LED 灯罩

家居及消费品

各种外壳、摆动盘、厨房用具元件、封盖和盖子

外壳

适用于各种应用领域的外壳。

Watch John and find out how impact extrusions beats stamping and casting.

1. 原材料

在冲击挤压中,90% 的材料被“压制”为矩形或圆形铝片,经常也制作成穿孔铝片。不过,实际上也可以制造各种形状的铝片。我们最常加工 1000(纯铝)和 6000 组别(AlMgSi1 合金)的合金。根据协商,也可以使用其他铝合金,除此之外,我们还可以加工铜镁合金。按照客户要求,我们的供应商会对原材料进行超声波测试。

1. 原材料

在冲击挤压中,90% 的材料被“压制”为矩形或圆形铝片,经常也制作成穿孔铝片。不过,实际上也可以制造各种形状的铝片。我们最常加工 1000(纯铝)和 6000 组别(AlMgSi1 合金)的合金。根据协商,也可以使用其他铝合金,除此之外,我们还可以加工铜镁合金。按照客户要求,我们的供应商会对原材料进行超声波测试。

2. Impact extrusion

Using horizontal knee lever mechanical presses with press forces ranging between 150 and 1200 tons, we produce parts with lengths of up to 500 mm and an outer diameters of up to 150 mm – developed and improved upon the early 1900s.

3. Heat treatment

State of the art heat treatment facilities can achieve strength values of T4, T6 and T8 conditions, providing parts with the desired mechanical properties they require.

4. Machining and processing

We use flexible and efficient machines for machining impact-extruded parts, not only for large batches, but also for lesser quantities.

2. Impact extrusion

Using horizontal knee lever mechanical presses with press forces ranging between 150 and 1200 tons, we produce parts with lengths of up to 500 mm and an outer diameters of up to 150 mm – developed and improved upon the early 1900s.

3. Heat treatment

State of the art heat treatment facilities can achieve strength values of T4, T6 and T8 conditions, providing parts with the desired mechanical properties they require.

4. Machining and processing

We use flexible and efficient machines for machining impact-extruded parts, not only for large batches, but also for lesser quantities.

5. Surface treatment

We meet your surface requirements with our long-time partners.

6. Assembly & packaging

We assemble and pack your part according to your requirements either manually or through reliable, cost-effective automation.

7. Quality

Our comprehensive quality management system is completely integrated in the process flow. Our production is certified in compliance with: ISO 9001, ISO 14001, ISO 45001 und IATF 16949.

5. Surface treatment

We meet your surface requirements with our long-time partners.

6. Assembly & packaging

We assemble and pack your part according to your requirements either manually or through reliable, cost-effective automation.

7. Quality

Our comprehensive quality management system is completely integrated in the process flow. Our production is certified in compliance with: ISO 9001, ISO 14001, ISO 45001 und IATF 16949.

Locations and certifications

With our production facilities in Austria (Marktl), Slovakia (Žarnovica), Germany (Rottenburg), USA (Waynesboro, VA) and China (Xinhui) and our high level of on-site availability, a Neuman partner is always close by. We are certified according to the following standards: ISO 9001, ISO 14001, ISO 45001 and IATF 16949.

就职诺文

如果您想有所作为,那么诺文就是您的正确之选。