Mobility

We get you moving safely and sustainabily.

Safe and sustainable

As global experts in aluminium manufacturing we drive the development of sustainable and safe mobility.

Automotive

Through intensive cooperation with automotive manufacturers and suppliers, we are constantly tapping new potentials for the use of aluminum. Wherever lightweight construction is the focus and at the same time high demands are placed on the material, our products are convincing. Our expertise ranges from materials development to process optimization, and our structural components and chassis components made of crash alloy are lightweight components that extend the range of passenger cars and increase their energy efficiency.

Chassis

Steering box

Joint fork

Precision profile

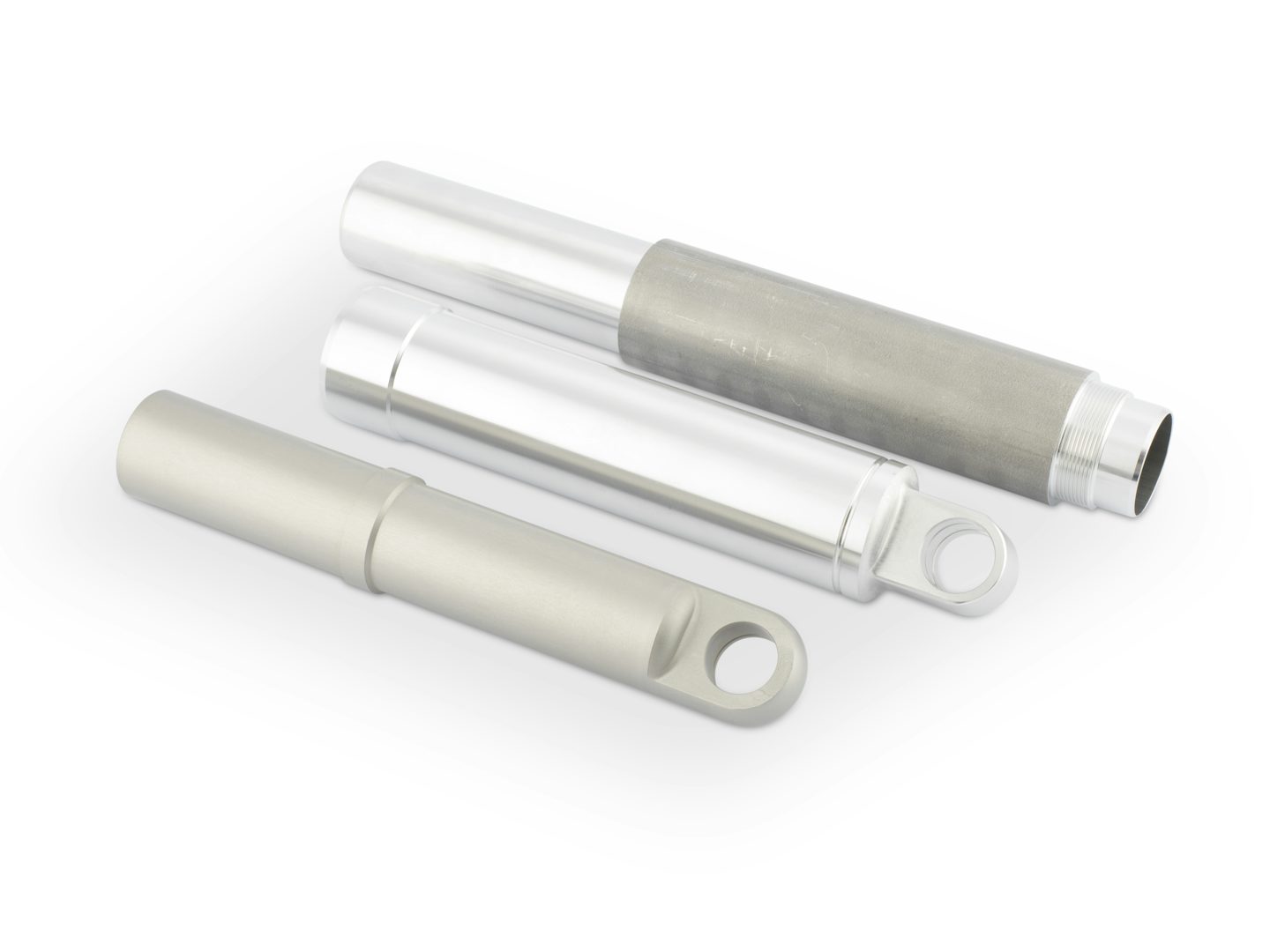

Shock absorber

Battery infrastructure

Air spring part

Damper components

Chassis insert

System components

E-motor housing

Housing for control electronics

Clamping ring

E-mobility

E-mobility

We have been involved in electromobility since its inception and are still experiencing an ever-increasing demand for innovative component solutions in the field of electric drives. Since 2013, we have been producing several million battery pressure plates and tie rods annually for the BMW i3. We are proud to shape the next generation of electromobility: the BMW Gen-5 battery.

E-mobility products

Pressure plate for battery box

Tie rod for battery box

Battery case e-bike

E-motor housing

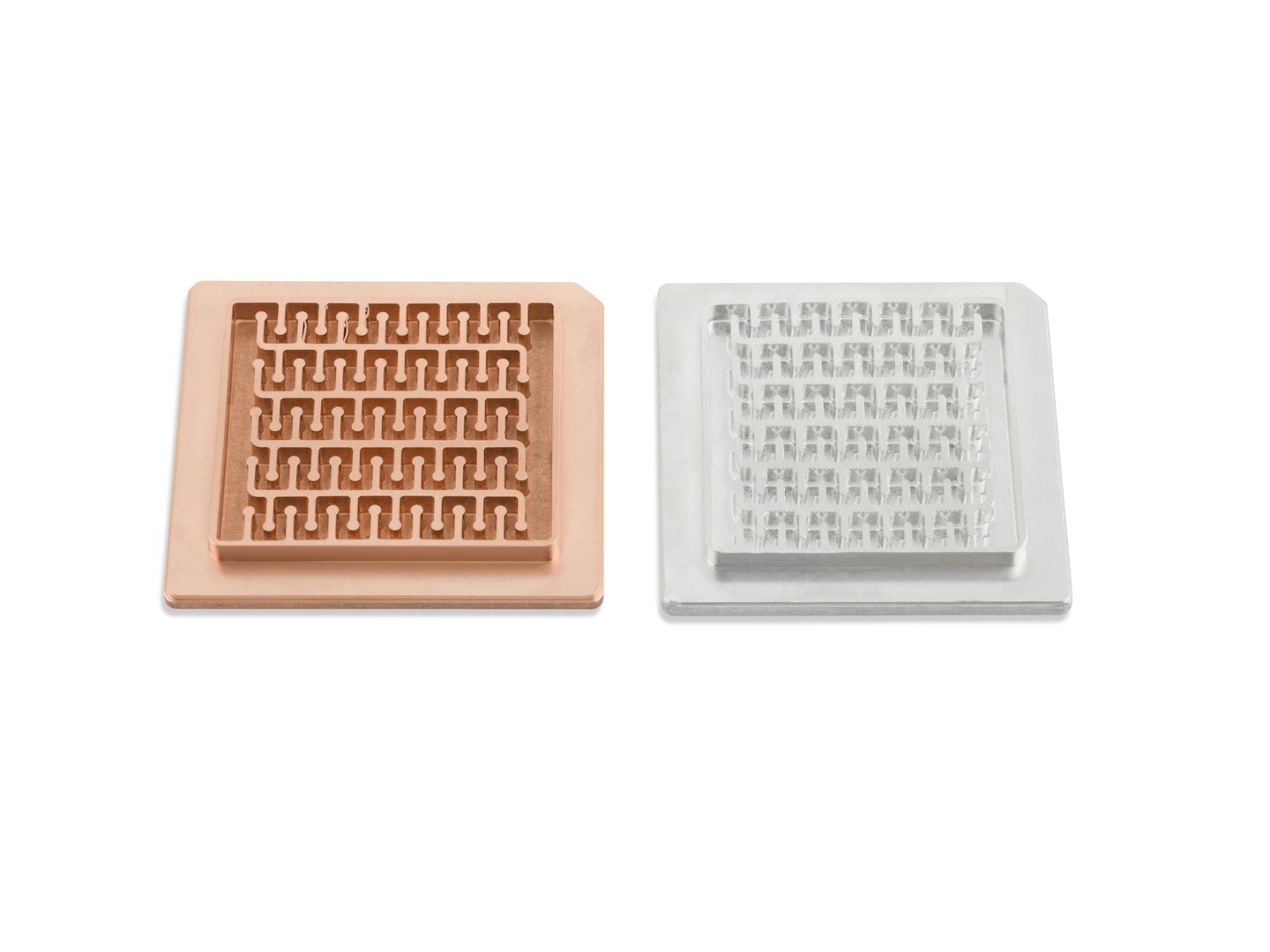

Heat sink

E-motor housing

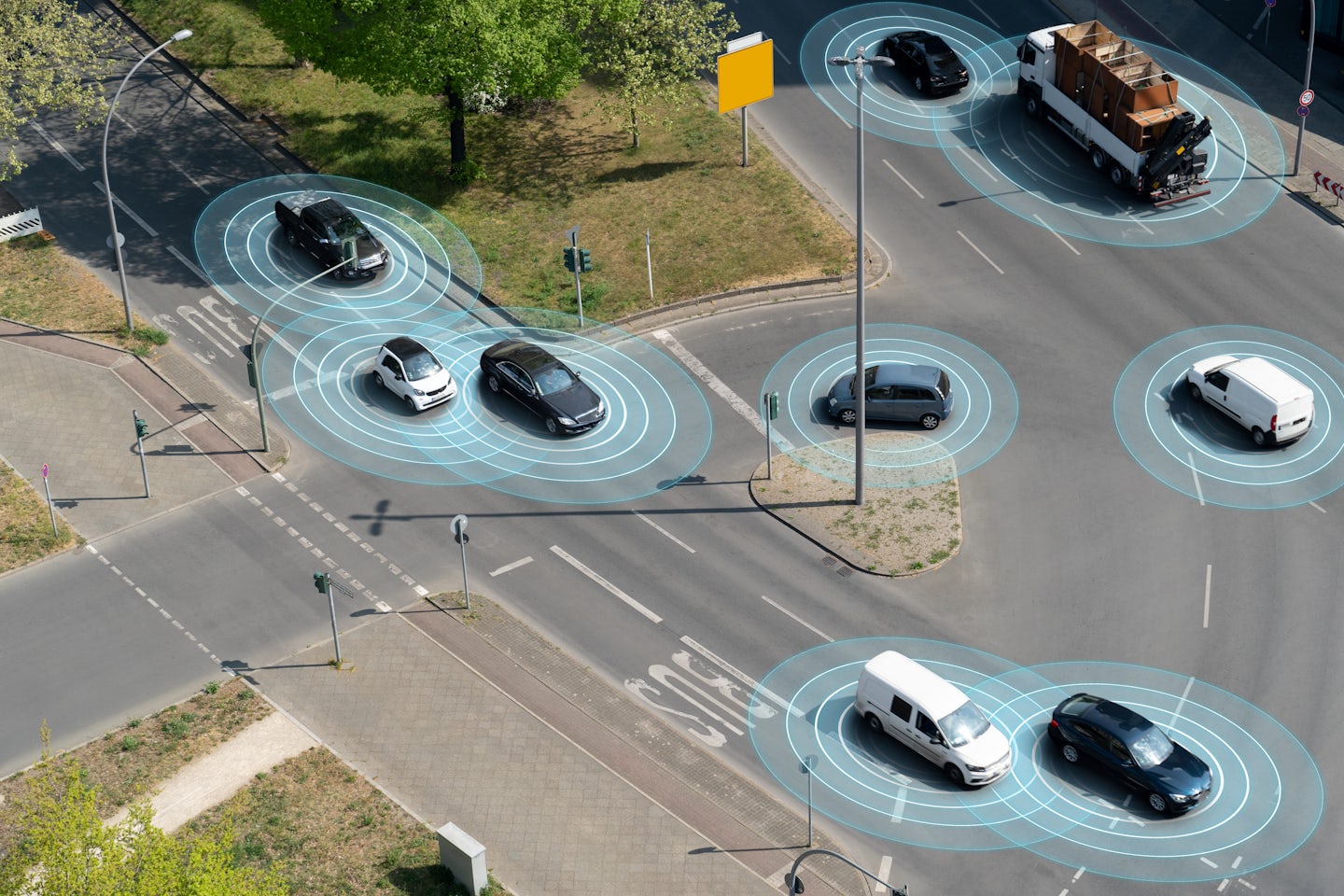

ADAS

ADAS

The share of sensors for (partially) autonomous driving is continuously increasing. More and more computing power is built directly into the sensors, and the space required for this is being designed smaller and smaller. With the aid of the impact extrusion process, complicated internal geometries combined with a very thin housing wall can be produced.

ADAS and electronic components

Camera body lens carrier

Park sensor membrane

Radar housing

Heat sink

Camera body set

Camera body

Radar carrier plate

Safety

Safety

For safety-relevant components in the chassis area, even high-performance cars such as McLaren or AMG rely on continuously cast products from Neuman Aluminium. Our structural components and chassis components made from crash alloys not only increase the range of the vehicles but also significantly enhance driving safety.

Safety products

Crash structure rear floor

Airbag housing

Positioning element for brake

Crash structure rear

Crash structure rear

Seat belt tensioner

Public transport

With its lightness and high payload, long service life and low maintenance costs, aluminum also impresses in the public transport sector. The extensive use of aluminum in trains means that speeds of over 350 km/h can be achieved on the rails. Almost all subways and commuter trains in Europe are now made of aluminum, and city buses with aluminum bodies offer a lightweight and economical alternative to conventional buses.

Public transport products

Lighting profile

Equipment room profile

Vehicle equipment

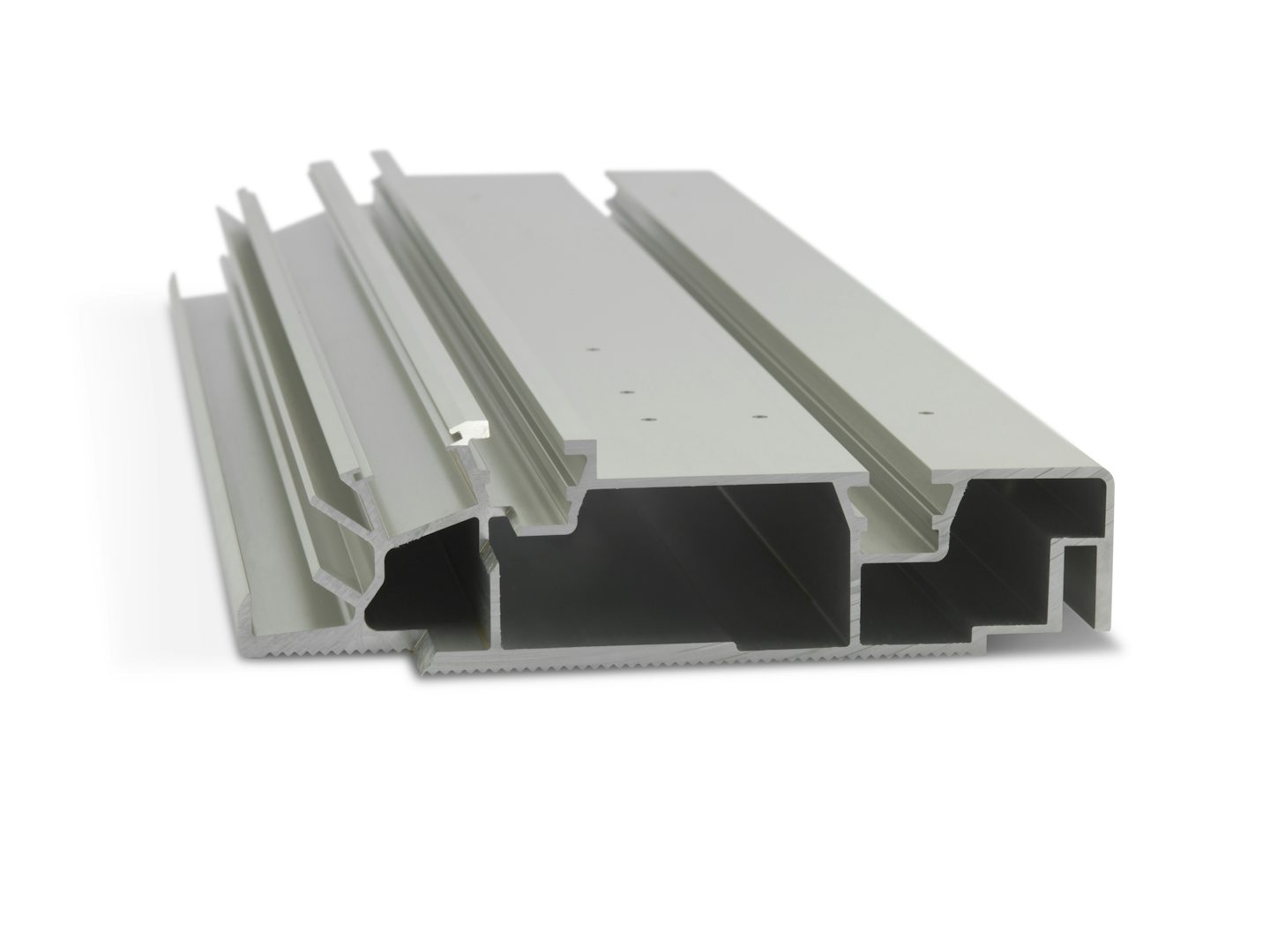

Roof opening systems

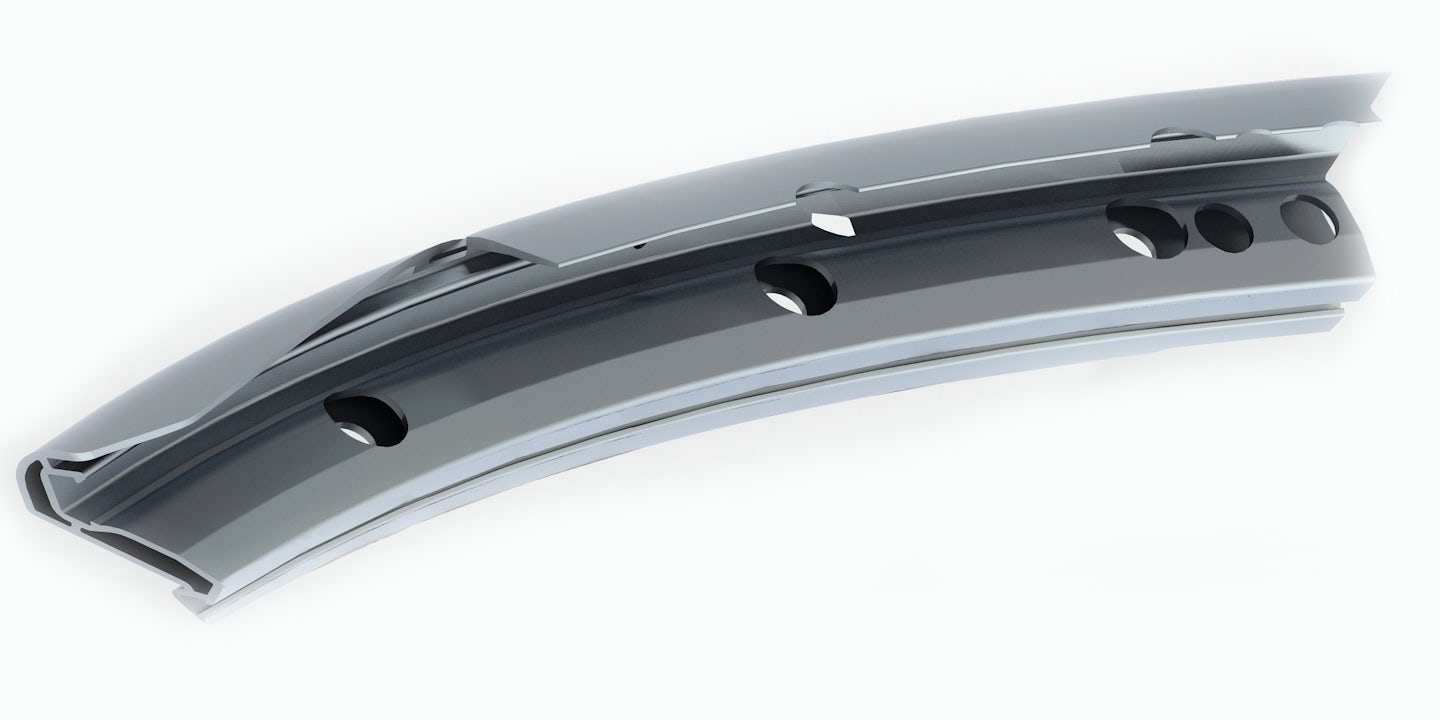

We are experts in the field of roof opening systems and offer the best quality with our fully automated production lines for bending, embossing, punching, milling, deburring, anodizing and assembly. We develop forward-looking ideas and savings opportunities for our customers and are a cooperative, reliable and transparent partner from the sample to beyond the end of series production.

Solutions for roof opening systems

Clamping bracket for convertibles

Seal retaining strip

Guide rail for panoramic roofs

Mobility news

Highest standards

Highest standards

We set ourselves apart from the competition not only with our high technological, ecological and social standards but above all with our ability to implement these standards in an economically sound manner.

Work for Neuman Aluminium

Move the world with us!